|

NOS info page:

Q: How does nitrous work?

A: Nitrous oxide is made up of 2 parts nitrogen and one part oxygen (36% oxygen by weight).

During the combustion process in an engine, at about 572 degrees F, nitrous breaks down and releases oxygen. This extra oxygen

creates additional power by allowing more fuel to be burned. Nitrogen acts to buffer, or dampen the increased cylinder pressures

helping to control the combustion process. Nitrous also has a tremendous "intercooling" effect by reducing intake

charge temperatures by 60 to 75 degrees F.

This should help (or confuse) you on what kit/system to choose from. I personally have the dry setup.

This

should help answer a frequently asked question.

Here's an article by Matt Paul.

There are 2 basic types

of "bolt-on" nitrous system for the LT1, "Wet" systems, which inject additional fuel externally to the

conventional fuel delivery system (the stock fuel injectors), and "Dry" systems, which increase the amount of fuel

injected by the stock fuel delivery system. Obviously, there are advantages and disadvantages to each.

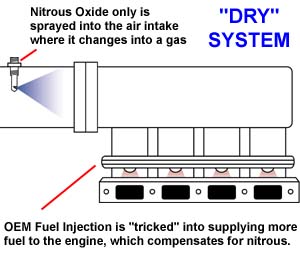

DRY SYSTEM

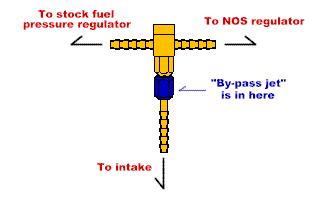

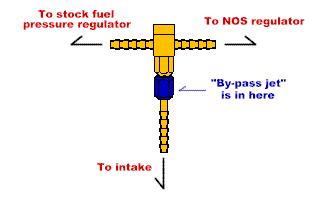

Dry nitrous injection systems (lets use the NOS 5176 kit as an example) use the stock fuel injectors to add additional

fuel into the combustion chamber by increasing the in-line fuel pressure (to the neighborhood of 80 PSI or so). By raising

the fuel pressure (and keeping the injector pulse width constant), additional fuel is delivered into the combustion chamber.

The NOS kit does this by applying positive pressure to the fuel pressure regulator, which in turn increases the fuel pressure

above the maximum stock levels.

This type of system has a few major advantages. First, it requires no plumbing

for the additional fuel delivery. Second, FUEL DOES NOT FLOW THROUGH THE ENTIRE INTAKE MANIFOLD. Lastly, as the nitrous pressure

in the bottle fluctuates, the amount of fuel delivered will fluctuate in the same amount (since the system is using the nitrous

pressure against the regulator to boost the fuel).

There are some disadvantages to this type of system. First,

the stock injectors may lock up at the 80-90 PSI fuel pressures that the system needs. Second, the amount of nitrous delivered

to each cylinder varies slightly (since it will not be consistently distributed in the intake manifold), while the amount

of fuel is the same. Either one of these can cause the air/fuel mixture to a given cylinder to go on the lean side.

WET SYSTEM

Wet nitrous systems inject both nitrous and fuel into the intake via a plate between the throttle

body and intake manifold or via an injection nozzle (or nozzles) prior to the throttle body.

The biggest advantage

to this type of system is that the nitrous/fuel proportion delivered to each cylinder is consistent (although the amount delivered

varies from cylinder to cylinder for the same reason that the amount of nitrous delivered varies with a dry system).

The disadvantages to this type of system are that since the manifold isn't designed to flow fuel, the fuel may "puddle"

in the intake manifold (although a good rev on the engine after shutting down the nitrous system will clear this). Second,

the nitrous solenoid will have to be periodically rebuilt (the seals deteriorate slightly due to the exposure to the fuel

vapors). Lastly, if the nitrous pressure fluctuates too high, it may cause the air/fuel mixture to lean out on some cylinders

As you can see, the common disadvantage to each system is the lack of a consistent amount and/or ratio of

nitrous/fuel to all cylinders. The "cure" to this is a direct plumbed nitrous injection system. These types of systems

use individual nitrous/fuel injectors for each cylinder, but are mucho expensive!

After deciding on your nitrous

system of choice, there are a number of other items that need to be upgraded or at least checked out before you can "get

it on".

N2O System Maintenance! click here

NOS FAQ

Jetting for a dry manifold NOS kit:

40hp 34 nitrous/44 fuel

50hp 37 nitrous/42 fuel

60hp 38

nitrous/42 fuel

70hp* 41 nitrous/36 fuel

80hp* 44 nitrous/34 fuel+

90hp* 46 nitrous/34 fuel+

(*)Larger fuel pump recommended/(+)requires a .040" shim be placed in

the co2 regulator.(this

is the large apparatus between the two solenoids

the top will unscrew from it) you also may have to experiment with

leaning out the fuel jet for maximum performance. Also make sure the

line between the Stock FPR (Fuel Pressure

Regulator) is hose clamped or that you are using the NOS fuel pressure safety switch otherwise you might break something you

don't want to fix. later!

Keep in mind that Fuel pressures should run between 40-50 psi to run safely on N2O,

anything below will run lean!

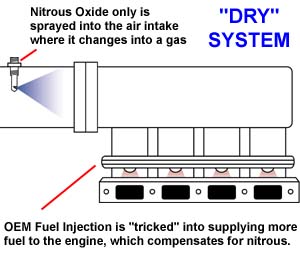

These are three basic types of nitrous systems: dry, wet, and direct port. The most misunderstood is the

"dry" type of system. A "dry" nitrous system simply means that the fuel required to make additional power with nitrous will

be introduced through the fuel injectors (remember, fuel makes power, nitrous simply lets you burn more of it). This keeps

the upper intake dry of fuel. NOS accomplished this by two methods. First, is to increase the pressure to the injectors by

applying nitrous pressure from the solenoid assembly when the system is activated. This causes an increase in fuel flow just

like turning up the pressure on your garden hose from 1/2 to full. The second way we can add the required fuel is to increase

the time the fuel injector stays on. This is accomplished by changing what the computer sees, basically tricking the computer

into adding the required fuel. In either case, once the fuel has been added the nitrous can be introduced to burn the supplemental

fuel and generate additional power.

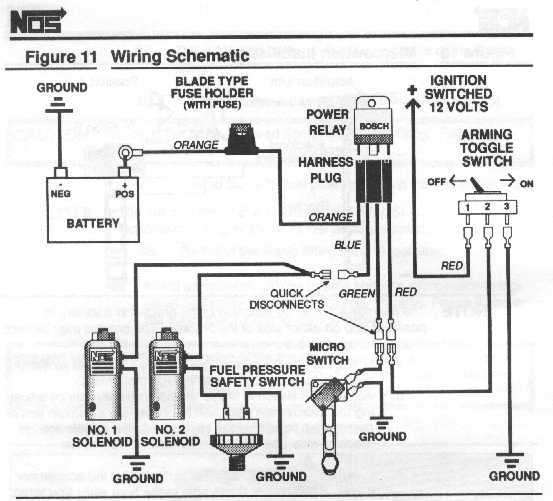

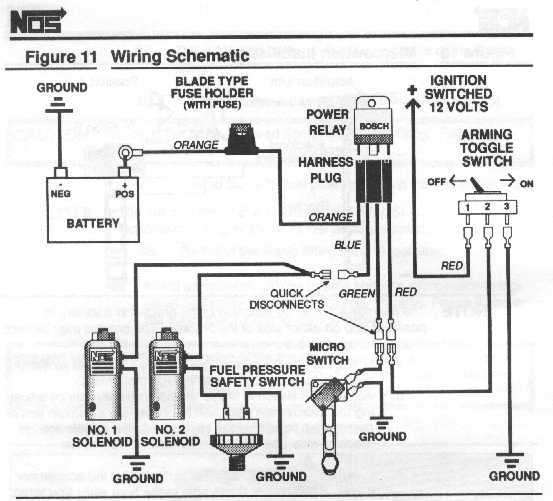

Click lower pic for applications and picture of set up

Click lower pic to enlarge Wiring Schematics

The second type of nitrous kit is the "wet" style of kit. These kits include carburetor plate systems and add nitrous

and fuel at the same time and place (normally 3-4" ahead of the throttle body for fuel injected applications or just

under the carb as with plate systems). This type of system will make the upper intake wet with fuel. These systems are best

used with intakes designed for wet flow and turbo/supercharged applications. The reason for this is the fact that fuel flows

differently than air or nitrous. This difference in flow characteristics can lead to distribution problems and, in some cases,

intake backfires. Intakes designed for wet flow (such as with carburetors) cause much less separation of the nitrous/air,

and fuel. Because modern fuel injection intakes are designed to flow air only, they have tighter turns and a more compact

design as a result. Thus, they generally do not make good candidates for wet flow nitrous systems.

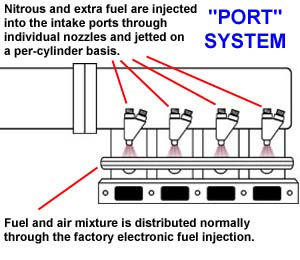

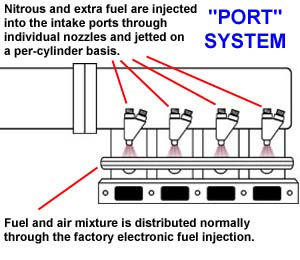

The last type of system is the direct port system. Just as it's name implies, it introduces the nitrous

and fuel directly into each intake port on an engine. These systems will normally add the nitrous and fuel together through

a nozzle known as a Fogger nozzle. The fogger nozzle mixes and meters the nitrous and fuel delivered to each cylinder. This

is the most powerful and one of the most accurate type of systems. This is due to the placement of the nozzle in each runner,

as well as the ability to use more and higher capacity solenoid valves. A direct port system will have a distribution block

and solenoid assembly which delivers the nitrous and fuel to the nozzles by way of connecting tubes. Because each cylinder

has a specific nozzle and jetting (both nitrous and fuel), it is possible to control the nitrous/fuel ratio for one cylinder

without changing that of the other cylinders. These systems are also one of the more complicated systems when installation

is considered, as the intake must be drilled, tapped, and the "plumbing" made to clear any existing obstructions. Because

of this and the high output of these systems, they are most often used on racing vehicles built for the strain of such high

horsepower levels.

Click lower pic for applications and more details

Click picture for performance gains!

|